THE MOST SUSTAINABLE & ADVANCED

COLORATION TECHNOLOGY

Hands a Better World to Our Future Generations

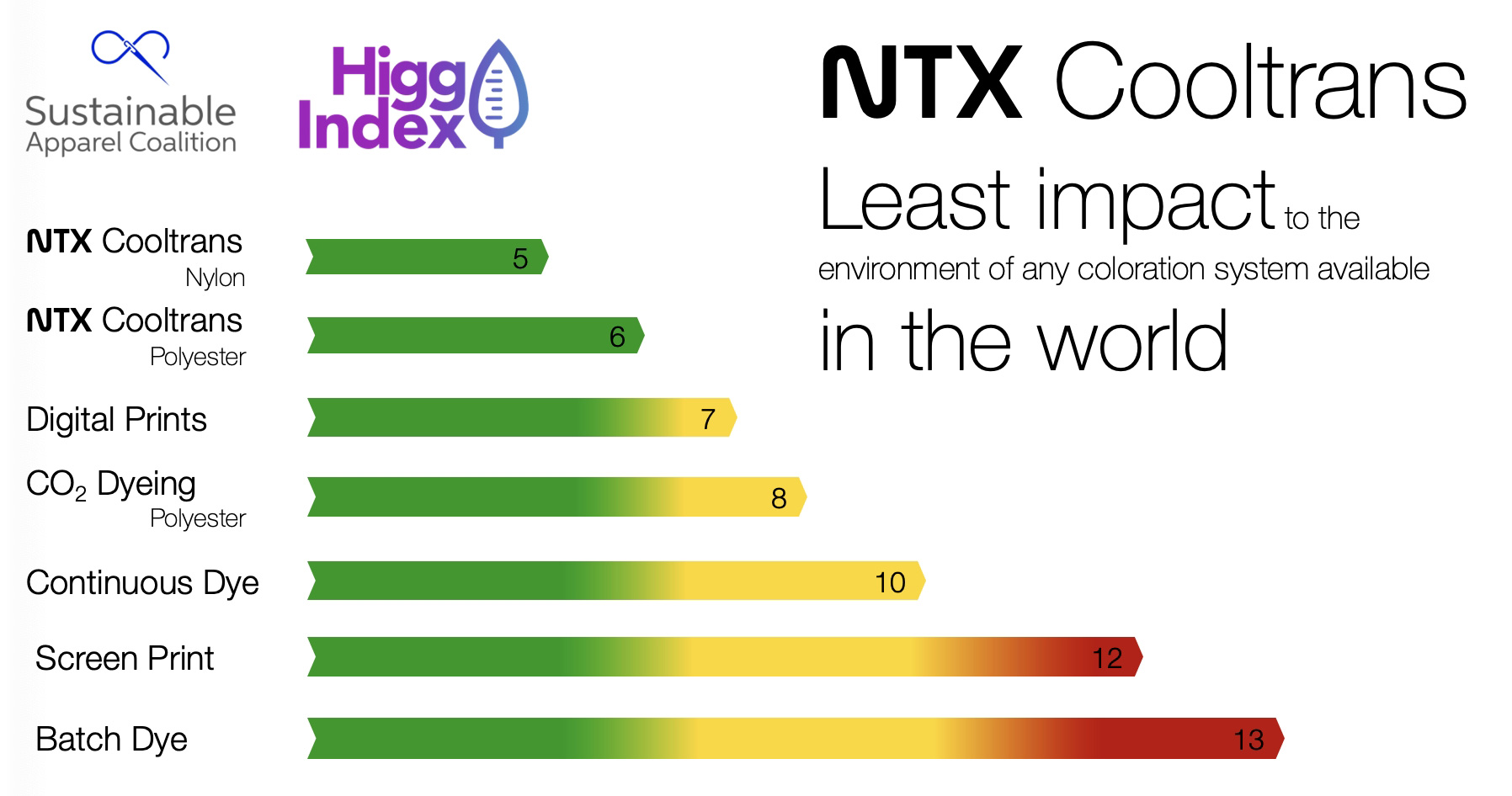

Least impact to the environment of any coloration system available

READ MOREONE FOR ALL

Colors and artwork are precisely & accurately transferred with best in industry color fastness, right first time, everytime.

NTX Facility

China

Cambodia

Vietnam

Thailand

Indonesia

China

Feilu

Feilu (Xinxiang, Henang) is our flagship joint venture setup with Bailu Fibers for the artwork print, solid color print dyeing and specialty coloration manufacture of knits and woven materials. Feilu is the only NTX system partner who has adopted the full line of NTX Cooltrans printing and dyeing systems with the intent of creating high quality and genuinely eco-friendly coloration system to address China domestic textile and global specialties market that is economically competitive.

Cambodia

Luentech (LTS)

LTS is a joint venture setup with Luen Thai, for artwork print and solid color print dyeing of knit material manufacture in Cambodia. Luen Thai is a global industry consolidator and multi-product expert in apparel and accessories as well as an innovator in fashion technology. Luen Thai is proactively pushes for a culture of becoming eXtraOrdinary (XO) everyday, striving for excellence as we move towards our vision of Sustainable Shared Success Through Reinvention.

Vietnam

FHNT

FHNT is a joint venture setup with Fuhsun Fiber industries for artwork print and later solid color print dyeing of knit material manufacture in Vietnam. Founded in 1963, FuHsun Fiber Industries has over 50 years of experience producing synthetic knitted fabrics for some of the world’s most famous sports apparel brands at the highest level of quality that they expect. FuHsun’s products, including a high volume of sustainable recycled fabrics, are consistently featured in hers with a strong and well-rounded portfolio, taking advantage of Taiwan’s position as a major globigh-profile sporting events such as the FIFA World Cup and the Olympics. FuHsun will continue the investment in sustainability innovation to handle the fast pace of the modern apparel industry.

VTT – Coming in 2022

VTT is a joint venture setup with Luen Thai & Viet Tien Garment Corporation for artwork print and solid color dye of woven material manufacture in Vietnam. Viet Tien, established since 1976, one of the largest garment manufacturers in Vietnam and annual capacities of 80,000,000 units of garments. Beside the international market, Viet Tien is also one of the largest domestic brands with 1,000+ stores nationwide. With the latest technologies, advanced machinery, full setup R&D Center, LEAN system and Green Factory with LEED Platinum certificate, making Viet Tien one of the global leaders in textile industrial.

Thailand

T-Tech

T-Tech is a joint venture setup with Thong Thai Textile for fast react artwork print knit material manufacture in Thailand. With 60+ years of experience in knitted fabric, Thong Thai textile is recognized as one of the most trusted fabric mills in Thailand. We knit and dye fabrics in cotton, polyester and also blended yarn.

Indonesia

T1NT

T1NT is a cutting-edge joint venture setup with P.T. Textile One Indonesia (TOI) for artwork print and solid color print dyeing of knit & woven material manufacture in Indonesia. TOI is a manufacturing base which merges traditional textile manufacturing excellence with data-driven decision making processes which maximize automation and sustainability. We intend on setting the benchmark for next generation textile manufacture. Our team consist of seasoned industry veterans and fresh entries in the industry in a flat hierarchy, creating an engaging learning environment with the most cutting-edge technologies. Thus providing new perspective in how to tackle industry challenges and create new innovations.

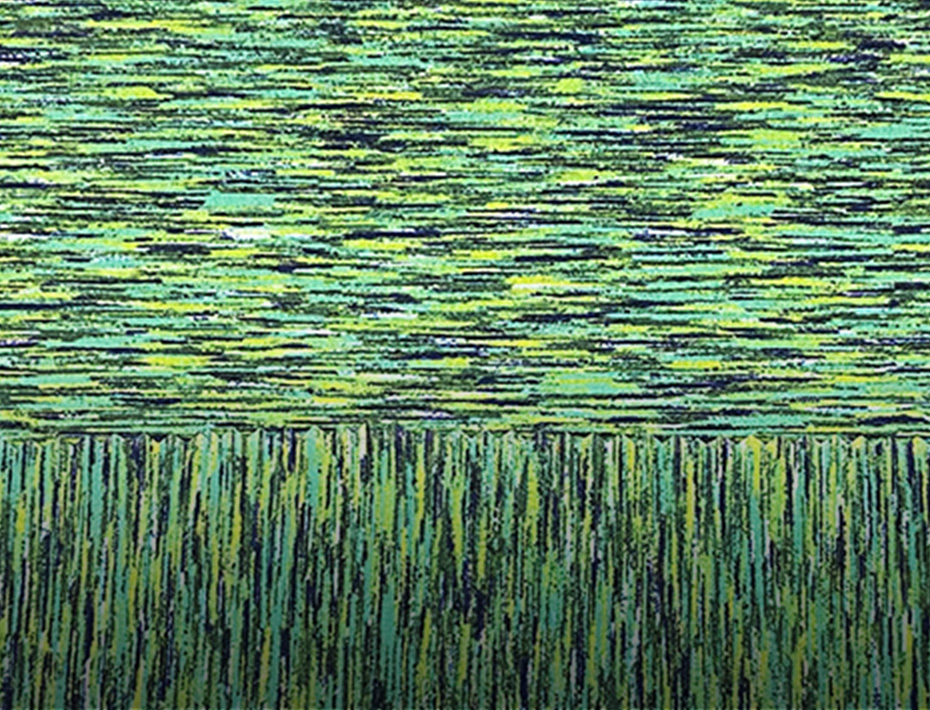

NTX® Cooltrans®

Applications

Versatile application on all fibers / filaments

Double / Single sided print

Double / Single sided print

Denim

Heather

Solid

Applied Areas

Apparel

Textile Accessories

Home Textile

FAQ of NTX® Cooltrans®

Sustainability in Textiles – Everything You Need to Know

We believe that we can’t let PERFECT be the enemy of GOOD

While NTX was founded as a research organization focused on idealistic sustainability goals, we believe in a practical approach to transforming the textile industry into a more eco-friendly and sustainable ecosystem. With that in mind we adhere to the following principles:

- We are committed to developing and implementing solutions that can have a dramatic impact today rather than waiting for the perfect solution to be ready tomorrow.

- We do not wait and nitpick until the solution is perfect but rather proactively implement gradual actionable improvements with the confidence that the cumulative accrual will bring us closer to perfection.

- We focus on solutions that can impact a great number of stakeholders, rather than innovations that can only be afforded by the top 1% of global consumers.

- We look for improvements that address the fundamental ecological threats rather than solutions that simply meet superficially set standards and try to get around the underlying issue.

What is the environmental impact of the textile industry?

There are four main areas where the textile industry has a big impact on the ecological system:

- Water consumption – a host of recent studies indicate that the textile industry consumes upwards of 93 billion cubic meters annually, that’s enough to fill 37 Million Olympic size swimming pools. A great bulk of the water consumption is the result of the coloration process, other factors such as ground water needed to cultivate cotton also play a role.

- Water pollution – an estimated 20% of global wastewater is caused by the coloration and finishing processes. This is the result of the use of hazardous materials and chemical dyes. More recently the presence of microfibers in our waterways is making headlines, this is primarily caused by synthetic fibers shed during washing cycles.

- Greenhouse gas emissions – traditional textile plants are heat intensive environments utilizing inefficient processes and machinery resulting in approximately 10% of global carbon emissions.

- Textile waste in landfills – finally the prominence of fast fashion has resulted in abundant production of clothing meant to be worn just a few times and discarded. In Europe for example, the citizenry consume about 26 kg of clothing per year and discard 11 kilos.

NTX was founded to specifically address these issues and offer a new way forward for the textile industry. NTX Cooltrans waterless coloration technology for instance is able to achieve accurate colorization of nearly any fabric material without heat, up to 90% reduction in water use, 40% reduction in dye use, while retaining uncompromising color fastness, hand feel, and functional performance.

What are sustainable textiles?

Sustainable textiles refer to material used for the manufacture of clothing or footwear that has been produced using eco-friendly technologies and/or using eco-friendly resources. Some environmentally friendly resources include sustainably grown crops used to create fabrics or recycled materials such as PET bottles. Regardless of the raw materials, the coloration and finishing processes have been a bottleneck to keeping the environmental impact to a minimum. This involves eliminating the use of toxic chemicals and heavy metals, as well as factories that don’t pollute or overuse the local water supply.

When looking to identify eco-friendly textile solutions, there are internationally recognized classification such as the Higg’s index to evaluate the environmental impact of a specific producer. In reality, when you step into a processing plant that claims to be sustainable, you should see a place that is clean and safe to work in. Instead of steam and vats of hot boiling odorous liquids, you would see something resembling the shiny stainless steel of a modern high tech production facility.

NTX® Cooltrans® technology has consistently outperformed mainstream textile production methods when utilizing third party assessment tools such as the Higg’s index.

Scaling Up Sustainable Denim Production: Stella Blu Joins NTX® Ecosystem

The WTiN Podcast- NTX® Cooltrans®

NTX® Gears Up For Growth With a Nearly US$200 Million in C2 Round Financing Led by Centurium Capital

NTX and Ananta Group Forge Strategic Alliance to Pioneer Factory of the Future

NTX and Ananta Group Forge Strategic Alliance to Pioneer Factory of the Future https://www.ntx.global/wp-content/uploads/2022/10/new-en.jpg 560 420 NTX //www.ntx.global/wp-content/uploads/2022/12/logo-ntx-c.pngScaling Up Sustainable Denim Production: Stella Blu Joins NTX® Ecosystem

Scaling Up Sustainable Denim Production: Stella Blu Joins NTX® Ecosystem https://www.ntx.global/wp-content/uploads/2022/10/new-en.jpg 560 420 NTX //www.ntx.global/wp-content/uploads/2022/12/logo-ntx-c.pngThe WTiN Podcast- NTX® Cooltrans®

The WTiN Podcast- NTX® Cooltrans® https://www.ntx.global/wp-content/uploads/2022/10/new-en.jpg 560 420 NTX //www.ntx.global/wp-content/uploads/2022/12/logo-ntx-c.pngNTX® Gears Up For Growth With a Nearly US$200 Million in C2 Round Financing Led by Centurium Capital

NTX® Gears Up For Growth With a Nearly US$200 Million in C2 Round Financing Led by Centurium Capital https://www.ntx.global/wp-content/uploads/2022/10/new-en.jpg 560 420 NTX //www.ntx.global/wp-content/uploads/2022/12/logo-ntx-c.png

For more information login to https://portal.higg.org/